- HOME

- Know Your Tech

- Operations management in 2026: Metrics and best practices

Operations management in 2026: Metrics and best practices

- Last Updated : February 9, 2026

- 635 Views

- 11 Min Read

Organizations worldwide will invest $81 billion in IT operations management software by 2028, significantly more than their current spending levels. This growth shows a fundamental shift in how businesses view operational efficiency as a competitive advantage rather than just an administrative challenge.

Highlights

- Operations management coordinates the conversion of inputs into outputs while optimizing cost, quality, speed, and flexibility across all business processes.

- Core operational functions include process design, capacity planning, scheduling, quality management, resource optimization, and continuous improvement initiatives.

- Operations managers plan strategic direction, oversee daily processes, coordinate teams, monitor performance metrics, solve problems, and communicate with stakeholders.

- Key operational metrics include cycle time, quality rates, resource utilization, on-time delivery, unit costs, and customer satisfaction scores.

- Automation enhances operations management by reducing manual coordination, improving accuracy, speeding decisions, providing real-time visibility, and enabling data-driven improvements.

Operations management determines how work flows through your organization, how resources get allocated, how quality gets maintained, and how processes improve over time. Strong operational practices directly affect your profit margins, customer satisfaction, and ability to scale.

This blog post explains operations management fundamentals, covering core responsibilities, key metrics, and effective implementation approaches. Plus, you’ll also learn how automation strengthens operational performance across different business functions and industries.

What is operations management?

Operations management coordinates activities that convert inputs like labor, materials, equipment, and technology into outputs in the form of products or services. This includes planning workflows, allocating resources, maintaining quality standards, and improving processes continuously.

For example, when a consulting firm manages project delivery, operations management could cover client intake processes, consultant scheduling, project tracking systems, quality reviews, and billing coordination. Each element works together to deliver services efficiently while meeting quality standards and financial targets.

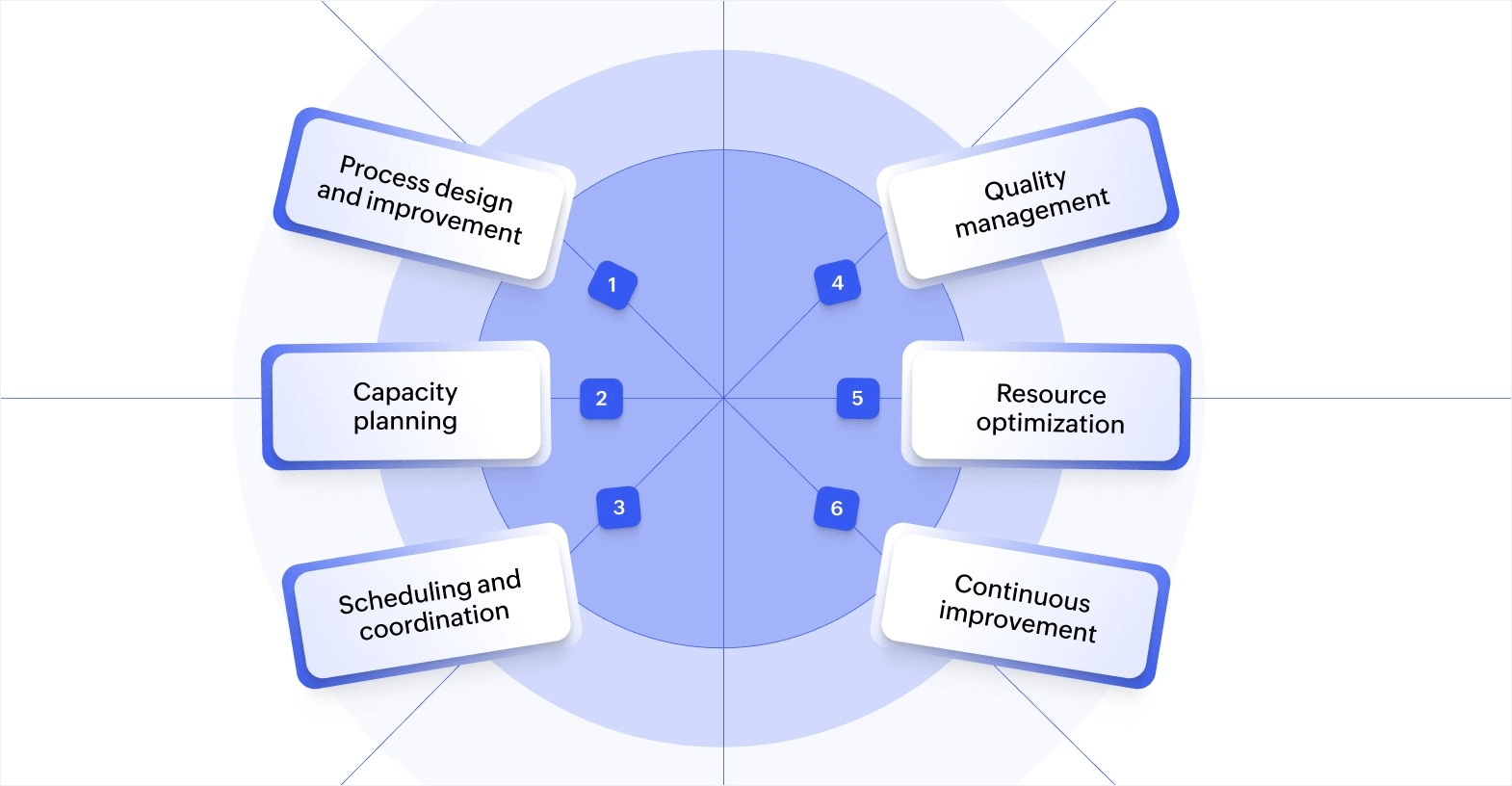

Core operations management responsibilities

The goal of operations management is to optimize cost, quality, speed, and flexibility simultaneously. Here are some of the core responsibilities in operations management:

1. Process design and improvement

Creating efficient workflows involves mapping how work moves through your organization, identifying unnecessary steps, and designing better sequences. For instance, a manufacturing company might redesign its order fulfillment process to reduce hand-offs between departments, significantly reducing processing time.

2. Capacity planning

Determining how much work your systems can handle requires analyzing current capabilities, forecasting demand, and planning for growth. For example, a healthcare clinic managing patient appointments needs capacity planning to balance doctor availability, exam room usage, and support staff schedules without creating bottlenecks or excessive wait times.

3. Scheduling and coordination

Sequencing tasks and allocating resources at the right times prevents delays and maintains smooth operations. This includes production scheduling, staff shift planning, equipment maintenance timing, and project milestone coordination across teams. For instance, a distribution center could coordinate inbound shipments, warehouse storage allocation, and outbound delivery schedules to prevent dock congestion and ensure smooth product flow.

4. Quality management

Maintaining standards requires defining quality criteria, implementing checks at key process points, tracking defect rates, and addressing root causes when problems occur. For instance, a software company could use quality management to review code before releases, test functionality, and monitor production systems for errors.

5. Resource optimization

Making the best use of available staff, equipment, materials, and budget involves analyzing utilization rates, identifying idle capacity, and reallocating resources to match priorities. For instance, a retail chain can optimize inventory placement across stores based on local demand patterns rather than distributing stock equally.

6. Continuous improvement

Regular process refinement through methods like lean principles and waste reduction creates ongoing efficiency gains. Teams identify improvement opportunities, test changes, measure results, and implement successful modifications across operations. For example, a customer service team might test different call routing methods, measure resolution times and satisfaction scores, then implement the approach that delivers the best results.

What does an operations manager do?

Operations managers oversee the implementation and improvement of operational processes. Their daily work involves several key activities that keep business functions running effectively.

- Strategic planning and goal alignment: Setting operational targets that support broader business objectives, for example, reducing production costs by 10% or improving order accuracy to 99.5%. This includes long-term planning for capacity expansion, technology adoption, and process changes.

- Process oversight and improvement: Monitoring how work flows through systems, identifying bottlenecks or inefficiencies, and implementing solutions. For instance, an operations manager might notice that approval delays slow purchasing, then implement automated workflow routing to speed decisions.

- Team coordination and resource allocation: Assigning work to appropriate team members, balancing workloads, and ensuring necessary resources are available when needed. This includes coordinating between departments to prevent gaps or duplicated effort.

- Performance monitoring and metrics tracking: Reviewing operational data regularly to spot trends, measure progress toward goals, and identify problems early. Operations managers track metrics like production output, quality rates, delivery times, and resource utilization.

- Problem-solving and decision-making: Addressing operational issues quickly, whether equipment failures, supplier delays, quality problems, or capacity constraints. This requires analyzing situations, evaluating options, and implementing solutions that minimize disruption.

- Stakeholder communication: Keeping teams, executives, and partners informed about operational status, challenges, and improvements. Clear communication ensures everyone understands priorities and can coordinate effectively.

These responsibilities require balancing immediate operational needs with long-term improvement initiatives. Effective operations managers maintain current performance while building systems that support future growth and changing requirements.

Key operation management metrics to track

Measuring operational performance helps identify improvement opportunities and track progress over time. Several metrics provide clear insight into how efficiently your operations function.

| Metric | What it measures | Why it matters |

| Cycle time and throughput | How long processes take from start to finish, and how many units you complete in a given period | Shorter cycle times with maintained quality indicate better efficiency |

| Quality rates and defect tracking | The percentage of outputs meeting standards on the first attempt, and where errors occur in processes | Reveals specific stages needing improvement and tracks the effectiveness of quality initiatives |

| Resource utilization | How effectively you use available capacity in staff time, equipment operation, or facility space | Identifies idle resources or capacity constraints that limit growth |

| On-time delivery performance | The percentage of commitments met by promised dates for internal deadlines or customer deliveries | Directly affects customer satisfaction and reveals process or capacity problems |

| Cost per unit | Total expenses divided by output volume show efficiency trends over time | Indicates whether operational improvements reduce costs while maintaining quality |

| Customer satisfaction scores | Feedback metrics like Net Promoter Score or satisfaction ratings | Reflects how well operations meet customer needs and predicts retention |

Different metrics matter more depending on your industry and business model. For instance, manufacturing operations typically focus heavily on quality rates and throughput, while service businesses prioritize cycle time and customer satisfaction. Track metrics that directly connect to your operational goals and customer requirements.

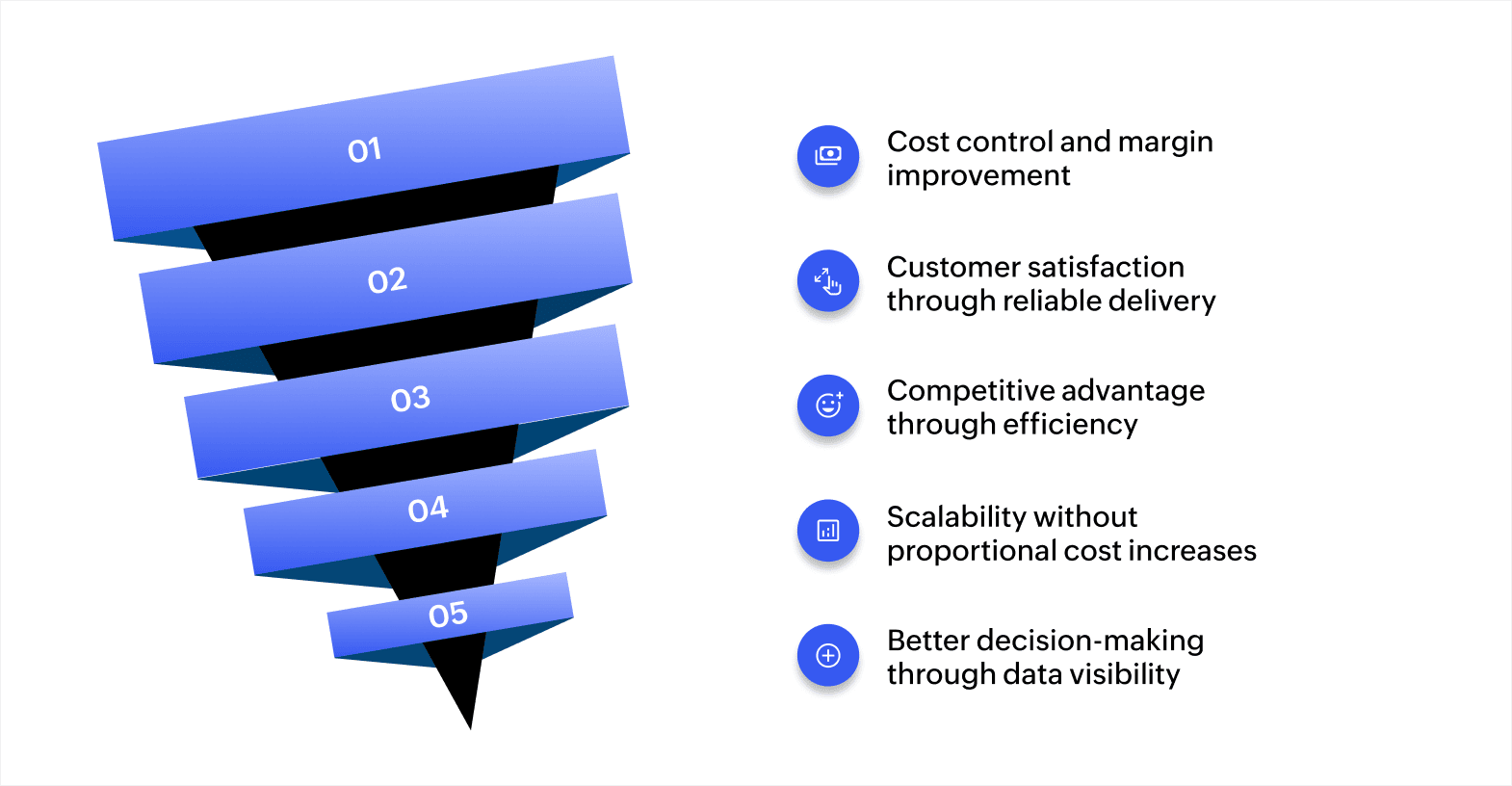

Why operations management matters for business success

Strong operations management creates competitive advantages that directly affect financial performance and market position. Several factors make operational excellence important for sustained business success.

- Cost control and margin improvement: Efficient operations reduce waste, minimize rework, optimize resource use, and lower overhead expenses. Each improvement flows directly to profit margins without requiring price increases or additional sales.

- Customer satisfaction through reliable delivery: Consistent quality, reliable timing, and smooth processes create positive customer experiences. For instance, a distribution company that ships orders accurately and on time builds trust that drives repeat business and referrals.

- Competitive advantage through efficiency: Companies that deliver faster, more reliably, or at lower cost than competitors win market share. Operational efficiency creates pricing flexibility and service capabilities that differentiate your business.

- Scalability without proportional cost increases: Well-designed operations handle increased volume without requiring proportional growth in staff, equipment, or expenses. A software company with automated onboarding could add customers without expanding support teams at the same rate.

- Better decision-making through data visibility: Understanding how operations actually perform enables informed choices about investments, process changes, and resource allocation. Real-time operational data reveals opportunities and problems that spreadsheets and manual tracking miss.

These benefits compound over time. Organizations that consistently improve operations build increasing advantages over competitors who still manage through manual processes and reactive problem-solving.

How automation enhances operations management

Automation changes how operations function by handling routine coordination, data collection, and decision triggers without constant manual intervention. This creates several meaningful improvements in operational performance.

Reduces manual coordination effort

Automated workflows move work between stages, assign tasks to appropriate team members, and trigger next steps based on completion or conditions. For instance, when a purchase order gets approved, automation could create inventory records, schedule receiving appointments, and update financial systems without manual data entry at each step.

Improves accuracy and consistency

Systems follow defined rules exactly every time, eliminating errors from manual processes like data entry, calculation, or routing decisions. An automated quality check validates required fields, format requirements, and business rules before allowing work to proceed.

Speeds response times and decision-making

Immediate notifications, automatic escalations, and real-time data access let teams act on issues faster. When inventory falls below reorder points, automated alerts let purchasing respond immediately rather than discovering shortages during weekly reviews.

Provides real-time visibility into operations

Automated data collection and dashboard updates show the current status without manual reporting work. Operations managers can see backlogs, bottlenecks, and performance trends instantly rather than waiting for end-of-period reports.

Enables data-driven improvements

Tracking operational metrics automatically creates historical patterns that reveal improvement opportunities. A service organization analyzing automated time tracking data might discover that certain request types consistently take longer, indicating a need for process refinement or additional training.

How to transform operations using automation: Step-by-step

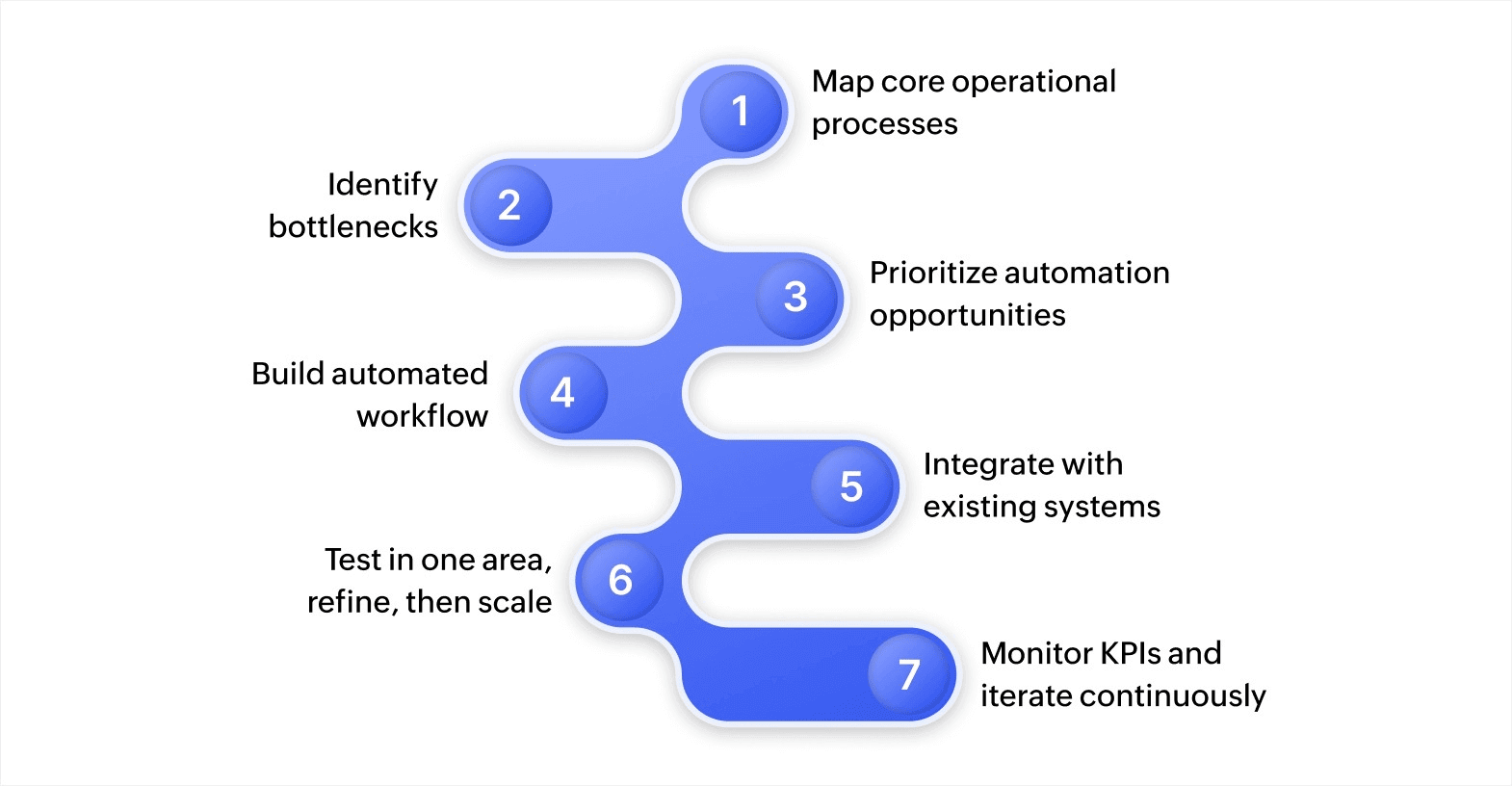

Implementing automation effectively requires a systematic approach that addresses your specific operational needs while managing change carefully. This step-by-step process helps organizations improve operations without disrupting ongoing work.

1. Map core operational processes

Document how work actually flows through your organization from initiation to completion. This includes order-to-cash cycles, procurement workflows, production sequences, support request handling, and any other repeating processes. Map current states properly, including workarounds and manual steps, rather than ideal processes.

2. Identify bottlenecks

Analyze where delays occur, errors concentrate, rework happens frequently, or costs run high. Look for manual hand-offs between systems or teams, approval delays, data entry duplication, and waiting time between process stages. Talk with team members doing the work daily since they often know exactly where problems occur.

3. Prioritize automation opportunities

Evaluate potential improvements based on impact and implementation difficulty. High-impact, low-difficulty opportunities should go first. For instance, automating a data entry task that takes 10 hours weekly and causes frequent errors delivers quick value, while redesigning your entire production planning system requires more time and resources.

4. Build automated workflows and approval processes

Create the actual automation using tools appropriate for your technical capabilities and needs. This might include configuring workflow automation in existing systems, building custom applications with low-code platforms, or implementing specialized software. Start with one process rather than attempting organization-wide changes simultaneously.

5. Integrate with existing systems

Connect your automation to current tools like ERP systems, CRM platforms, inventory management, support ticketing, and financial software. Integration eliminates data duplication and ensures information flows automatically between systems. For instance, when sales creates an order in the CRM, integration could automatically create production work orders and update inventory forecasts.

6. Test in one area, refine, then scale

Test your automation in a limited scope first, such as one team, one location, or one process type. Monitor results closely, gather feedback from users, identify issues, and make adjustments. After proving the approach works and refining based on real use, expand to other areas. This reduces risk and improves outcomes compared to immediate full-scale implementation.

7. Monitor KPIs and iterate continuously

Track the metrics that matter for each automated process: cycle time reduction, error rates, cost savings, and customer satisfaction impact. Review performance regularly to ensure automation delivers expected benefits and identify additional improvement opportunities. Operations management remains an ongoing activity, not a one-time project.

Operations management across different industries

Operational priorities shift based on your products, how you serve customers, and what regulations apply. Knowing these differences helps you focus on what matters most for your specific industry.

| Industry | Primary operational focus | Common challenges | Typical automation priorities |

| Manufacturing | Production efficiency, quality control, and inventory management | Coordinating suppliers, minimizing defects, optimizing equipment use | Production scheduling, quality tracking, and inventory reordering |

| Healthcare | Patient scheduling, resource allocation, care coordination | Regulatory compliance, staff scheduling, and patient wait times | Appointment management, patient records, bed allocation |

| Retail | Inventory turnover, fulfillment speed, and customer service | Managing SKU variety, seasonal demand, and omnichannel coordination | Inventory tracking, order processing, and customer communications |

| Technology | Project delivery, service uptime, feature deployment | Balancing speed with quality, coordinating distributed teams | Issue tracking, release management, capacity planning |

| Professional services | Resource utilization, project profitability, and client satisfaction | Matching skills to projects, tracking billable time, and managing scope | Time tracking, project scheduling, and invoice generation |

Each industry benefits from focusing operational improvements on areas that most directly affect customer satisfaction and financial performance. A healthcare provider gains more from improving patient scheduling than optimizing supply chain logistics, while a manufacturing company prioritizes production efficiency over service delivery speed.

Best practices for effective operations management

Several approaches help organizations build stronger operational performance over time. These practices work across industries and business sizes.

Use data to guide decisions and measure performance

Track metrics that reveal how operations actually function rather than relying on assumptions or impressions. Review data regularly to spot trends, identify problems early, and measure improvement initiatives. For instance, a logistics company tracking delivery times by route could identify specific areas needing attention.

Standardize processes where possible while allowing flexibility

Document standard operating procedures for repetitive tasks to ensure consistency and quality. This reduces training time, minimizes errors, and creates clear expectations. However, build in flexibility for situations requiring judgment or adaptation rather than rigidly enforcing procedures that don't fit every case.

Focus on continuous improvement

Create regular opportunities for teams to suggest process improvements, test changes, and implement successful modifications. Small, incremental improvements compound over time to create significant operational gains.

Build strong cross-functional coordination

Operations rarely stay within a single department. Effective coordination between sales, production, logistics, finance, and support prevents gaps, reduces delays, and improves customer experience. Regular communication and shared visibility into operational status help teams work together effectively.

Invest in training and skill development

Well-trained teams work more efficiently, make better decisions, and adapt to changes more easily. Ongoing training in both technical skills and operational processes helps everyone contribute to operational excellence.

Balance efficiency with quality

Cost reduction and speed improvements mean little if quality suffers. Monitor quality metrics alongside efficiency measures to ensure you're actually improving operations rather than creating problems. For instance, pushing for faster production without adequate quality checks could increase defect rates and customer returns.

The best operational improvements increase both efficiency and quality simultaneously by eliminating error-prone manual steps and standardizing successful approaches.

Build operational systems with Zoho Creator

Many businesses manage operations using spreadsheets, email coordination, and disconnected tools that create visibility gaps and slow decision-making. As operations grow more complex, these limitations make it harder to maintain efficiency, track performance, and implement improvements.

Zoho Creator is an AI-powered low-code application development platform that helps you build custom operational systems matching your specific processes and requirements. You can create applications for workflow automation, resource scheduling, quality tracking, performance monitoring, or any operational need without extensive coding knowledge.

Operations teams can design custom dashboards displaying real-time metrics, build automated approval workflows that route work based on your rules, and create mobile-accessible systems that work wherever your teams operate. The platform also integrates with existing tools like ERP systems and CRM platforms to eliminate data duplication.

Operations don't need to stay complex or manual. Sign up for free today and start building operational systems with Zoho Creator.

FAQ

1. Can small businesses benefit from formal operations management?

Yes, operational improvements work at any scale. Small businesses often see proportionally larger benefits from process standardization, automation, and better coordination because inefficiencies consume more resources relative to total capacity.

2. How often should you review operational processes?

Conduct formal process reviews quarterly to identify improvement opportunities, but monitor key metrics continuously for early problem detection. Major changes like growth phases or new service launches warrant immediate operational review.

3. What causes most operational bottlenecks?

Manual hand-offs between systems or teams, approval delays, capacity constraints in specific resources, and poor coordination create most bottlenecks. Process mapping and workload analysis reveal where delays concentrate.

4. How does automation affect operations staff?

Automation eliminates repetitive coordination work, letting staff focus on problem-solving, improvement initiatives, and customer interaction. This typically requires training on new systems but creates more valuable work rather than reducing headcount.

5. How do you balance operational efficiency with flexibility?

Standardize routine processes while building decision points where judgment applies. Document core procedures but empower teams to adapt when situations require different approaches rather than rigidly enforcing procedures in every case.

Stephen

StephenStephen is a product marketer at Zoho Creator. An avid writer, he plies his trade evangelizing low-code during the day and pens songs at night. Sneakerhead and sushi enthusiast too.